Production Process

Discover the meticulous craftsmanship and quality control that goes into every PureSip Studio product. From material selection to final packaging, we ensure excellence at every step.

Material Selection

We carefully select premium materials including food-grade stainless steel 304, borosilicate glass, and high-quality ceramics. Each material is sourced from certified suppliers and undergoes rigorous quality testing to ensure safety, durability, and environmental compliance.

Key Features

- ✓Stainless steel 304/316 grade

- ✓Borosilicate glass (heat-resistant)

- ✓Food-grade ceramic materials

- ✓BPA-free components

Design Draft & Logo Placement

Our design team collaborates with you to create mockups and determine optimal logo placement. We provide digital proofs showing how your branding will appear on the final product, ensuring perfect alignment with your brand identity.

Key Features

- ✓Custom design consultation

- ✓Digital mockup creation

- ✓Logo positioning optimization

- ✓Color matching and approval

Surface Treatment

Advanced surface treatment processes including powder coating, electroplating, and baking finish are applied to achieve the desired aesthetic and protective qualities. These treatments enhance durability and create stunning visual effects.

Key Features

- ✓Powder coating in custom colors

- ✓Electroplating for metallic finishes

- ✓Matte and glossy finish options

- ✓Anti-scratch protective layers

Branding Process

Your logo is applied using precision techniques such as laser engraving for permanent marking, silk screen printing for vibrant colors, or UV printing for photographic quality. Each method is selected based on the material and desired effect.

Key Features

- ✓Laser engraving (permanent)

- ✓Silk screen printing (multi-color)

- ✓UV printing (full-color graphics)

- ✓Heat transfer printing

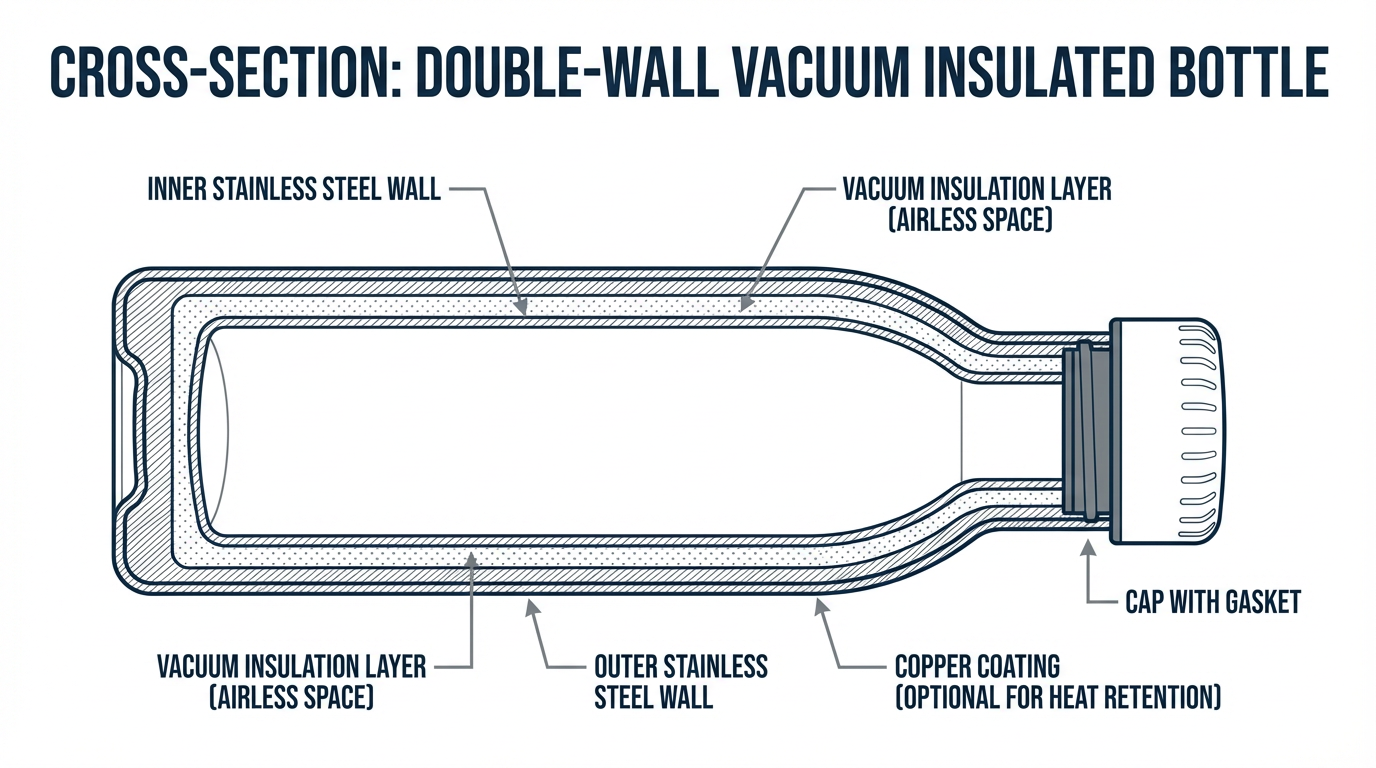

Assembly & Structure Testing

Components are assembled with precision, and vacuum insulation layers are tested for integrity. Thermal retention tests ensure products maintain temperature as specified, while leak tests verify seal quality.

Key Features

- ✓Vacuum layer integrity testing

- ✓Temperature retention verification

- ✓Leak-proof seal testing

- ✓Component fit inspection

Quality Inspection

Every product undergoes comprehensive quality control checks. Our inspectors examine surface finish, branding clarity, functional performance, and overall aesthetics to ensure only flawless items proceed to packaging.

Key Features

- ✓Visual inspection (scratches, defects)

- ✓Dimensional accuracy check

- ✓Branding quality verification

- ✓Functional performance testing

Packaging

Products are carefully cleaned and packaged in premium gift boxes or eco-friendly packaging as specified. Each item is protected to ensure it arrives in perfect condition, ready to impress your recipients.

Key Features

- ✓Premium gift box packaging

- ✓Eco-friendly packaging materials

- ✓Custom branded packaging options

- ✓Secure protective wrapping

Our Quality Commitment

At PureSip Studio, quality is not just a goal—it's a guarantee. Every product that bears our name has been crafted with precision, tested rigorously, and inspected thoroughly. We stand behind the excellence of our workmanship and the durability of our materials, ensuring that your branded drinkware makes a lasting impression.

Quality Inspected

Certified Standards

Production Stages

Ready to Start Your Custom Order?

Experience the PureSip Studio difference. Contact us today to discuss your requirements and receive a detailed quote.

Request a Quote