Why Your 500-Unit Custom Drinkware Order Takes 9 Weeks When the Quote Said 7

A Singaporean tech startup's 500-unit custom stainless steel bottle order was quoted 7 weeks but delivered in 9. The supplier blamed 'production delays,' but the real issue was changeover time—an invisible overhead that disproportionately affects small custom orders and is rarely disclosed in quotes.

A Singaporean tech startup ordered 500 custom stainless steel bottles for their Q3 product launch event. The supplier quoted 7 weeks. Nine weeks later, the bottles arrived—two weeks past the event date. When pressed, the supplier cited "production delays" and "unexpected scheduling issues." The startup assumed this was a capacity problem or a material shortage. It wasn't. The real culprit was something most buyers never see in quotes: production line changeover time.

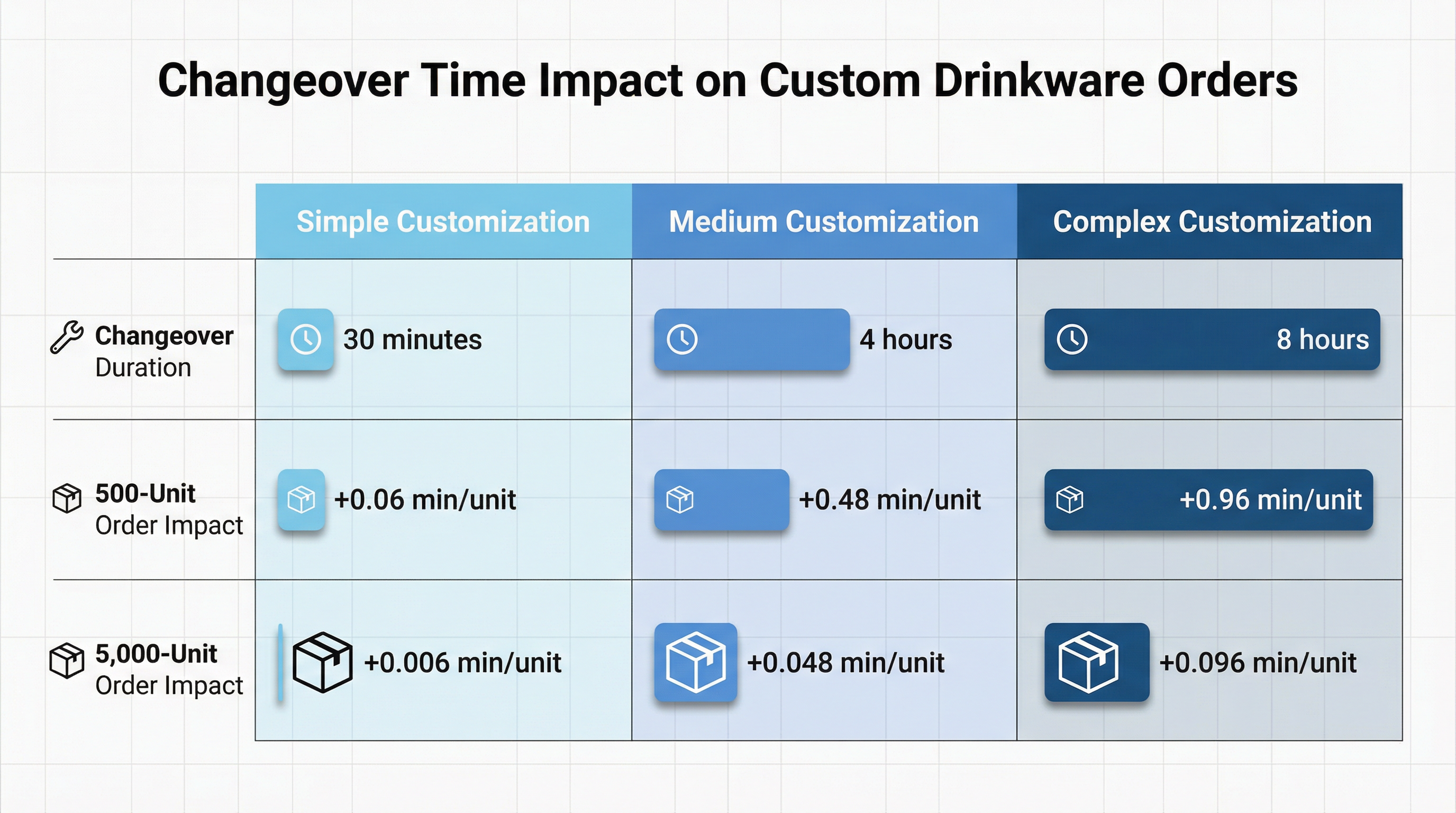

Changeover time refers to the period required to switch a production line from one product specification to another. For custom drinkware, this involves cleaning equipment, reconfiguring settings, replacing tooling (such as laser engraving programs or screen printing templates), running test batches, and performing quality checks before full production begins. Depending on the complexity of customization, changeover can range from 30 minutes for a simple label swap to 8 hours for a complete line reconfiguration involving powder coating color changes, curing oven recalibration, and new packaging setups.

Here's the problem: suppliers rarely itemize changeover time in their quotes. When a factory quotes "7 weeks production time," they're usually referring to the time needed to manufacture your order once the line is set up and running at full capacity. What they don't tell you is that your 500-unit order might sit in a queue for two weeks while the factory batches it with other similar orders to minimize changeover frequency. Or that your order requires a 6-hour changeover between two other clients' production runs, adding 1.5 days to your timeline that was never mentioned in the quote.

The economics of changeover time create a systematic bias against small custom orders. Consider the overhead calculation: a 4-hour changeover for a 500-unit order translates to 0.48 minutes of non-productive time per unit. The same 4-hour changeover for a 5,000-unit order is only 0.048 minutes per unit—ten times more efficient. Factories know this math intimately. When production schedules get tight, they prioritize larger orders because the changeover cost is amortized across more units. Your 500-unit order, which seemed perfectly reasonable when you placed it, suddenly becomes the "inefficient" job that gets pushed back whenever a 2,000-unit order from another client arrives.

This dynamic is invisible to buyers because changeover time is embedded in the supplier's internal scheduling logic rather than being presented as a line item in quotes. When you compare two suppliers offering "7-week lead times," you're not comparing apples to apples. Supplier A might run a highly standardized product line with 20-minute changeovers between jobs. Supplier B might serve 15 different clients with unique specifications, requiring 4-hour changeovers between each. Both quote 7 weeks, but Supplier B's timeline assumes your order will be batched with at least two other similar jobs to justify the changeover cost. If those other jobs don't materialize, your order waits.

The situation becomes more complex when you introduce customization variables that affect changeover duration. A stainless steel bottle with a standard powder coating color (white, black, or silver) might require only 2 hours of changeover time because the factory keeps those colors pre-mixed and the curing oven settings are standardized. But if you request a custom Pantone color match for your corporate branding, the changeover time jumps to 6 hours: the factory must mix a new batch of powder, run test coatings, adjust oven temperature and dwell time, and perform color consistency checks across multiple test pieces. Your quote still says "7 weeks," but the supplier is now assuming they'll batch your custom color job with at least one other client requesting a similar shade to justify the extended changeover.

Laser engraving presents a similar pattern. A simple logo engraving on a glass bottle requires uploading a new vector file to the laser system and running 3-5 test engravings to verify placement and depth—roughly 90 minutes of changeover time. But if your design includes fine text, gradient shading, or multi-layer engraving (common in premium corporate gifts), the changeover extends to 3 hours: the laser operator must adjust power settings, speed, and focal distance for each layer, run multiple test pieces, and perform microscopic inspection to ensure the engraving won't crack or fade after repeated washing. Again, your quote doesn't reflect this complexity because the supplier assumes they'll batch your job with other high-complexity engravings.

The batching assumption creates a hidden dependency that buyers never see. When you place a 500-unit order with custom specifications, the factory doesn't immediately slot you into the production schedule. Instead, they place your order in a "pending customization" queue and wait for other orders with similar specifications to arrive. If another client orders 300 units with the same powder coating color within two weeks, the factory batches both jobs together, performs one 6-hour changeover, and runs 800 units consecutively. Your lead time stays close to the quoted 7 weeks. But if no similar orders arrive, the factory faces a decision: perform a 6-hour changeover for your 500-unit job alone (economically inefficient), or delay your order until they accumulate enough similar jobs to justify the changeover cost. Most factories choose the latter, which is why your "7-week" order becomes a 9-week delivery.

This batching logic explains why reorder lead times are consistently 20-30% shorter than first-order lead times, even when order quantities are identical. It's not because the supplier has "gotten to know your requirements better" or because "the relationship has matured." It's because the changeover settings from your first order are saved in the factory's system. When your reorder arrives, the laser engraving program is already uploaded, the powder coating formula is documented, and the quality inspection parameters are pre-configured. Changeover time drops from 6 hours to 90 minutes because the factory only needs to verify settings rather than create them from scratch. Buyers often attribute this lead time reduction to intangible factors like trust or partnership, when in reality it's a mechanical consequence of changeover efficiency.

The invisibility of changeover time in quotes creates a systematic information asymmetry. When you request a quote, the supplier asks about quantity, material, customization requirements, and delivery timeline. But they rarely ask: "How flexible are you on delivery date if we need to batch your order with similar jobs?" or "Are you willing to accept a 2-week delay if no other clients order the same custom color within your production window?" These questions would expose the changeover batching assumption, so suppliers avoid them. Instead, they quote a lead time based on an idealized scenario where your order slots perfectly into an existing production run with minimal changeover overhead.

The problem compounds when you're working with multi-product suppliers who serve diverse industries. A factory producing custom drinkware for corporate clients, hospitality businesses, and retail brands must manage dozens of different specifications: stainless steel vs. glass vs. ceramic, powder coating vs. electroplating vs. anodizing, laser engraving vs. screen printing vs. pad printing, retail packaging vs. bulk packaging vs. gift box packaging. Each specification change requires a different changeover procedure with different durations. A supplier serving 20 clients with unique specs performs changeovers far more frequently than a supplier serving 5 clients with standardized specs. Both might quote "7 weeks," but the multi-product supplier's timeline is far more vulnerable to changeover-related delays because they're constantly switching between different setups.

This is where understanding the full production timeline from order placement to delivery becomes critical. Buyers who focus solely on the quoted lead time miss the structural factors that determine whether that timeline is achievable. Changeover time is one of those factors—it's not a hidden stage in the production process (like QC approvals or packaging customization), nor is it a seasonal capacity constraint (like Q4 peak demand). It's an order-specific overhead that scales inversely with order size and directly with customization complexity. The more customized your specifications, and the smaller your order quantity, the more vulnerable you are to changeover-related delays that were never disclosed in the original quote.

Experienced procurement teams mitigate this risk by asking suppliers three specific questions during the quoting process. First: "What is the changeover time required for our specifications, and is it included in the quoted lead time?" This forces the supplier to itemize changeover as a separate component rather than embedding it in a vague "production time" estimate. Second: "Do you batch orders with similar specifications, and if so, what happens if no similar orders arrive during our production window?" This exposes the batching assumption and allows you to negotiate a firm delivery date that doesn't depend on other clients' orders. Third: "What is the typical lead time difference between first orders and reorders for our specifications?" If the supplier quotes 7 weeks for first orders and 5 weeks for reorders, the 2-week gap is a proxy for changeover efficiency. A large gap (3+ weeks) suggests high changeover complexity or poor changeover standardization, both of which increase delivery risk.

Some buyers attempt to avoid changeover delays by requesting "priority production" or paying expedite fees. This rarely works as intended because priority status doesn't eliminate changeover time—it only moves your order ahead in the queue. If your order still requires a 6-hour changeover and the factory is running three other jobs before yours, priority status might save you 3-5 days of queue time but won't eliminate the 6 hours of changeover overhead. The only way to truly bypass changeover delays is to align your specifications with the factory's most frequently produced configurations. If the factory runs white powder-coated stainless steel bottles every week for multiple clients, specifying white instead of a custom Pantone color reduces your changeover time from 6 hours to 2 hours and eliminates the batching dependency entirely.

The changeover time blind spot also explains why some suppliers offer "quick-turn" or "express production" services with 30-50% shorter lead times at premium prices. These services aren't magic—they're simply production slots reserved for orders that require minimal changeover. A supplier offering "4-week express production" for stainless steel bottles is likely running a dedicated line for standard configurations (silver, white, or black powder coating; standard logo placement; bulk packaging) with 30-minute changeovers between jobs. Your 500-unit order fits into this express slot because it doesn't require the factory to reconfigure equipment or batch with other orders. The premium price reflects the opportunity cost of reserving line capacity for fast-turnaround jobs rather than batching multiple custom orders together.

The structural economics of changeover time create a paradox: the more you customize your drinkware to differentiate your brand, the more vulnerable you become to delivery delays that were never disclosed in the quote. A tech startup ordering 500 bottles with a custom Pantone color, gradient laser engraving, and premium gift box packaging might receive a "7-week" quote that's identical to a hospitality client ordering 500 bottles with standard white coating, simple logo engraving, and bulk packaging. But the tech startup's order requires 8 hours of total changeover time across multiple production stages, while the hospitality client's order requires 2 hours. The factory batches the hospitality order with three other similar jobs and delivers in 7 weeks. The tech startup's order sits in the customization queue for two weeks waiting for another gradient engraving job to arrive, then gets delayed another week when the custom color powder coating doesn't pass the first quality check. Final delivery: 10 weeks, with the supplier citing "production complexity" rather than admitting the delay was caused by changeover batching logic that was never explained upfront.

Buyers who understand changeover economics can negotiate more realistic timelines by offering flexibility that reduces the factory's batching pressure. If you're willing to accept a 2-week delivery window instead of a fixed date, the factory can slot your order into the next available changeover opportunity without forcing a dedicated setup. If you're ordering multiple SKUs (e.g., 300 bottles + 200 tumblers), requesting sequential production rather than parallel production allows the factory to perform one changeover per SKU instead of juggling multiple setups simultaneously. These concessions don't cost you anything in terms of product quality or total lead time, but they dramatically reduce the factory's changeover overhead and eliminate the batching dependency that causes most custom order delays.

The invisibility of changeover time in supplier quotes represents a fundamental information gap in B2B procurement. Buyers optimize for quoted lead time, unit price, and MOQ, but they don't optimize for changeover efficiency because suppliers don't disclose it. The result is a systematic pattern of "unexpected delays" that aren't unexpected at all—they're the predictable consequence of small custom orders being deprioritized in favor of larger, more standardized jobs that minimize changeover costs. Until buyers start asking about changeover time explicitly, and until suppliers start itemizing it in quotes, this blind spot will continue to cause delivery failures that both parties attribute to vague "production issues" rather than the structural economics of line switching.

Related Articles

Why Your July Quote Shows 8 Weeks But Your October Order Takes 12: The Capacity Queue You Never Saw

Most buyers request quotes during off-peak months and receive lead time estimates based on current capacity. When they place actual orders during peak season, they expect the same timeline. They don't realize that lead time quotes reflect snapshot capacity, not future allocation—and that peak season creates a priority queue where new orders wait weeks before production even begins.

Why Your Supplier's 8-Week Lead Time in March Becomes 11 Weeks in October

A Singapore-based technology firm learned this lesson the expensive way last year. In March, they ordered 800 custom stainless steel bottles with their company logo for an internal product launch. The...

Why Your Supplier's 8-Week Lead Time Quote Doesn't Match the 10-Week Reality You Experience

When comparing supplier quotes for custom drinkware, buyers often assume "lead time" is a standardized metric like MOQ or unit price. In practice, one supplier's "8-week lead time" might mean production completion, while another's means delivered to your warehouse—a difference that can derail corporate gifting deadlines.

Interested in Custom Drinkware?

Contact our team to discuss your requirements and receive a personalized quote for your corporate gifting needs.