Complete Guide to Custom Drinkware Customisation Process: Essential Reading for Singapore Enterprises

Comprehensive guide to custom drinkware procurement for Singapore enterprises. From MOQ negotiation to quality control, covering materials, printing, lead times, and risk management.

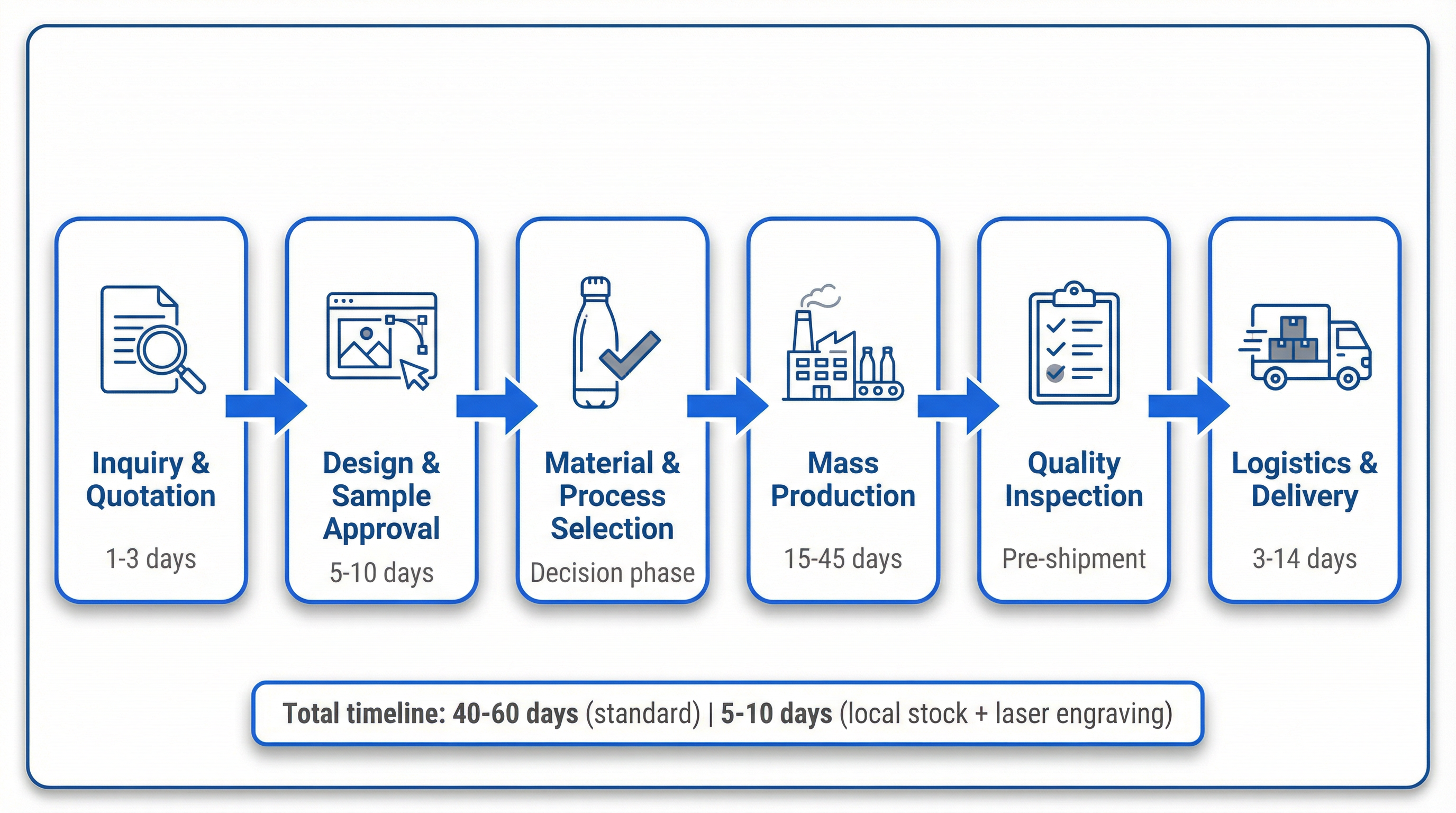

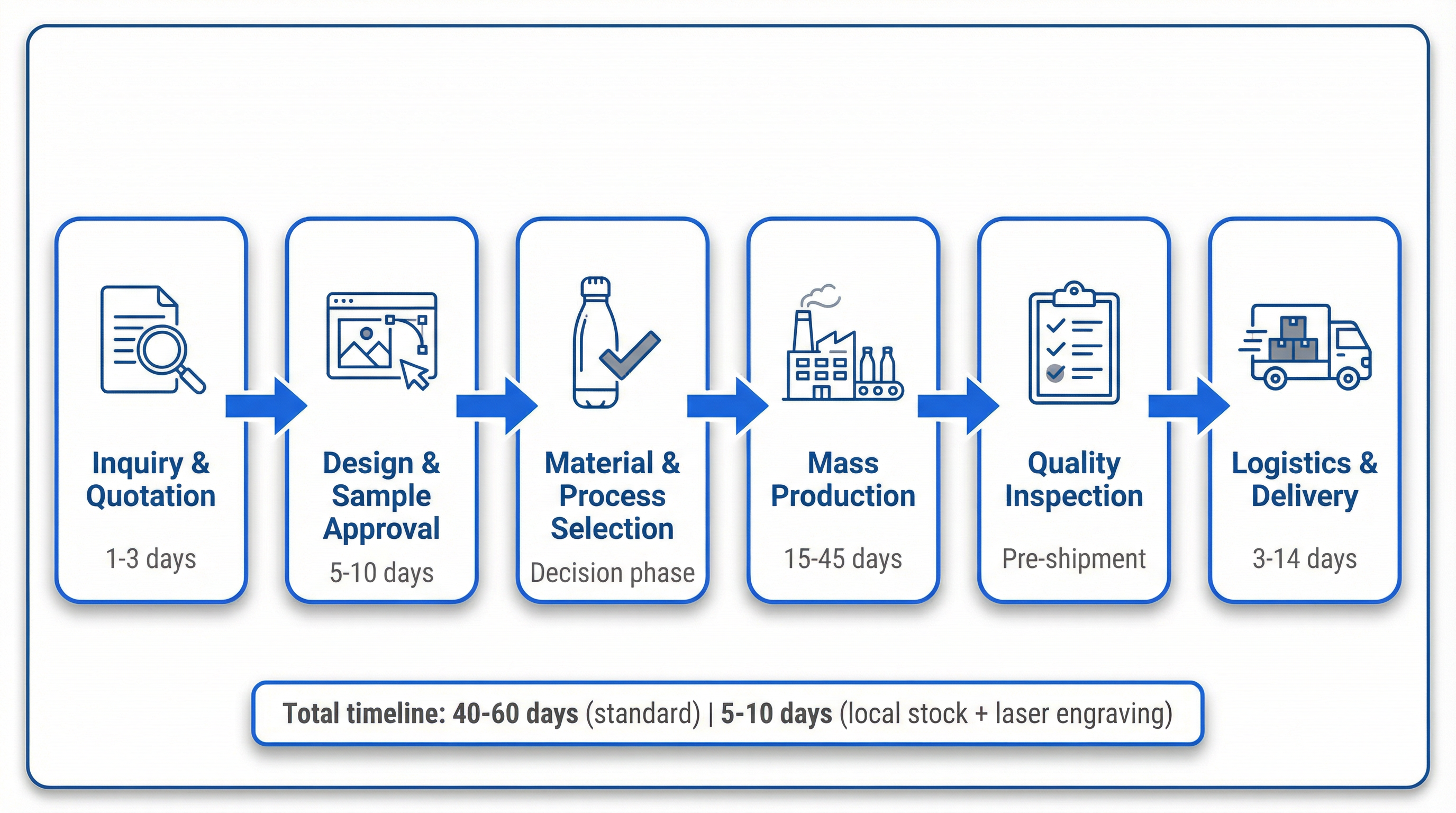

The custom drinkware customisation process comprises six critical stages: requirements confirmation and quotation (1-3 days), design mockup and sample approval (5-10 days), material and technique selection, bulk production (15-45 days depending on MOQ), quality inspection, and logistics delivery. The most common challenges Singapore enterprises face are underestimating lead time risks, overlooking how MOQ affects unit pricing, and failing to specify AQL quality standards in contracts. SMEs should prioritise local suppliers' flexibility and rapid delivery capabilities, whilst MNCs need to focus on brand consistency, compliance, and global distribution coordination. This guide provides Singapore enterprises with a complete roadmap from procurement decisions through to risk management for custom drinkware orders.

Why Custom Drinkware is a Critical Decision for Singapore Enterprises

In Singapore's corporate environment, custom drinkware is not merely a promotional item or staff gift—it represents a convergence of brand image, budget control, and Corporate Social Responsibility (CSR). Based on our experience assisting Singapore enterprises, many procurement managers underestimate the complexity of this decision when placing their first order.

Hidden Costs in Budget Control

The quoted unit price is just the tip of the iceberg. The true Total Landed Cost encompasses mould fees, printing setup charges, freight costs, GST (7%), and potential warehousing expenses. Consider a fintech startup based at Raffles Place: they initially saw a quote of SGD 8 per stainless steel vacuum bottle, but the actual cost per unit reached SGD 12. This was because the MOQ of only 100 units meant setup fees couldn't be amortised, compounded by air freight charges and premium pricing for urgent delivery.

For budget-conscious SMEs, we recommend prioritising local suppliers' stock designs with laser engraving, which can reduce lead times to 5-7 working days with MOQs as low as 50 units. For MNCs requiring globally consistent branding, annual procurement planning is essential—utilising "blanket orders" (total quantity orders with staged delivery) locks in lower unit pricing, with distribution scheduled according to each office's requirements.

Long-Term Impact on Brand Image

Custom drinkware functions as "mobile advertising"—every time an employee or client uses it, they engage with your brand logo. The durability of print quality directly affects brand professionalism. We encountered a manufacturing MNC in Jurong that chose the lowest-cost heat transfer printing method, only to find logos peeling off after three months, ultimately damaging their brand image.

For corporate gifts intended for long-term use, we recommend laser engraving or powder coating combined with screen printing. Whilst unit costs increase by approximately 15-25%, logos remain intact for 3-5 years without fading. This is particularly important for industries that value professional image, such as finance, legal, or consultancy sectors.

Compliance and Environmental Responsibility

When selecting custom drinkware, Singapore enterprises must ensure products comply with local regulations and international standards. All materials in contact with food or beverages must meet Singapore Food Agency (SFA) food safety standards—stainless steel should be SUS304 (18/8 food-grade stainless steel), whilst plastic materials must be BPA-free.

Furthermore, as the Singapore government advances the "Zero Waste Masterplan", enterprises choosing reusable custom drinkware as an alternative to single-use plastics not only align with CSR objectives but also build positive environmental credentials among employees and clients. For listed companies required to present concrete actions in corporate sustainability reports, this represents a quantifiable environmental contribution.

Practical Procurement Process and Common Practices for Singapore Enterprises

The custom drinkware procurement process can be divided into six stages, each with its theoretical best practices and practical execution challenges. Below is a complete workflow compiled from our experience assisting over 200 Singapore enterprises.

Stage One: Requirements Confirmation and Quotation (1-3 Working Days)

Theoretical approach: Procurement managers should first clarify quantity, budget, delivery timeline, and design requirements before requesting quotes from 3-5 suppliers.

Practical execution challenges: Many enterprises haven't finalised quantities when requesting quotes, leading to inconsistent quotation bases. For example, Supplier A quotes SGD 10 based on 500 units, whilst Supplier B quotes SGD 8 based on 1,000 units. The procurement manager mistakenly believes B is cheaper, but if only 500 units are ultimately ordered, B's unit price may adjust to SGD 11.

Singapore-specific business practice: Local suppliers typically expect face-to-face meetings or at least one phone conversation to establish trust. Pure email correspondence may be perceived as "not serious enough", affecting quotation priority. For first-time supplier collaborations, we recommend arranging an office visit or video conference—this is an important step in Singapore's business culture for establishing long-term partnerships.

Stage Two: Design Mockup and Sample Approval (5-10 Working Days)

Theoretical approach: Provide AI or EPS vector files for suppliers to create design mockups for confirmation, followed by physical sample production.

Practical execution challenges: The number of mockup confirmation iterations is the biggest variable affecting lead times. We've seen an extreme case where an advertising agency client, due to multiple internal stakeholders with conflicting opinions, revised the design mockup 12 times, extending the original 30-day lead time to 60 days.

Pitfall avoidance advice: Establish a single "design decision-maker" as the sole point of contact during the quotation stage to avoid multiple conflicting directions. Additionally, if logos contain gradients or intricate patterns, proactively ask suppliers about "how this design will actually appear on curved stainless steel surfaces", as flat mockups may differ from physical products.

Stage Three: Material and Technique Selection

This is the critical stage that determines product quality and cost. Common choices for Singapore enterprises include:

Material Selection:

- Stainless Steel (SUS304): Most popular among corporates, excellent insulation (maintains hot beverages for 6-12 hours), high durability, but higher unit cost (SGD 8-15). Suitable for finance, technology, and professional services sectors.

- Glass: Premium feel, suitable for executive gifts, but fragile with high transport costs. MOQ typically higher (from 500 units).

- Tritan Plastic: Lightweight, BPA-free, suitable for sports or outdoor activities, lower unit cost (SGD 4-8), but less premium brand image.

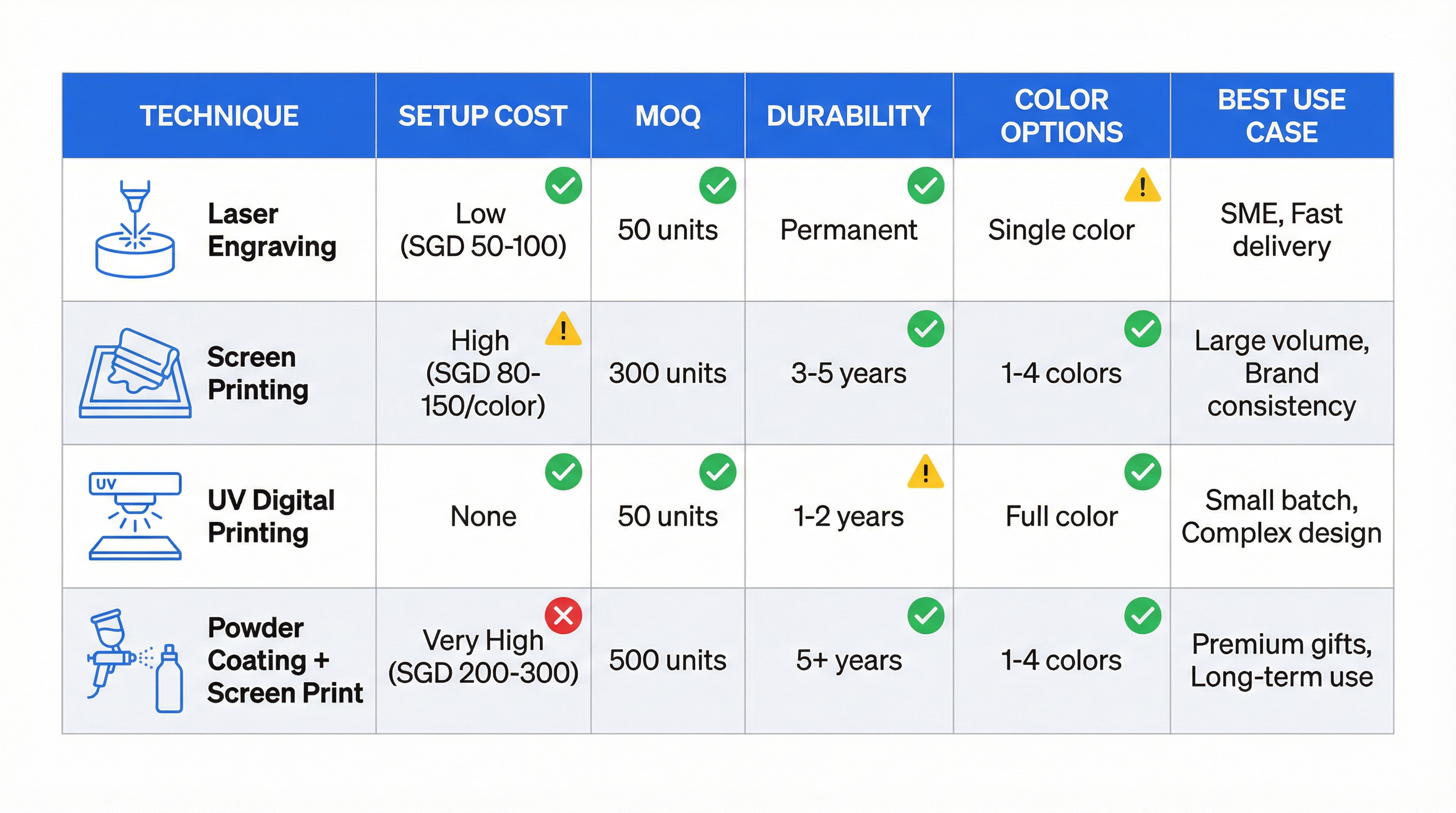

Printing Technique Selection:

- Laser Engraving: Permanent, suitable for simple logos, low setup fee (SGD 50-100), MOQ as low as 50 units. Limitation: only single colour (metal's natural colour).

- Screen Printing: Can display 1-4 colours, high colour saturation, excellent durability. Higher setup fee (SGD 80-150 per colour), suitable for MOQ 300+ units.

- UV Digital Printing: Can display full colour and gradients, no setup fee, but lower durability (approximately 1-2 years), higher unit cost. Suitable for small batches (50-200 units) with complex designs.

Trade-off Analysis: If you're a 100-person startup with limited budget requiring rapid delivery, we recommend "stainless steel + laser engraving" with MOQ 100 units, 7-10 day lead time, unit cost approximately SGD 9-12. If you're a 5,000-person MNC requiring globally consistent branding, we recommend "stainless steel + powder coating + screen printing" with MOQ 2,000 units, 30-40 day lead time, unit cost approximately SGD 7-9, but logos remain intact for 5+ years.

Stage Four: Bulk Production (15-45 Days)

Theoretical approach: After sample approval, suppliers commence bulk production whilst procurement managers await delivery.

Practical execution challenges: Ambiguity in defining the "starting point" for production lead times is the most common dispute. Does the supplier's quoted "30-day lead time" mean "30 days after sample approval" or "30 days after deposit receipt"? If mockup revisions delay sample approval, does the lead time extend accordingly?

Best practice for Singapore enterprises: Explicitly state in contracts "Lead time starts from the date of sample approval and receipt of deposit". Additionally, for urgent projects, enquire whether suppliers offer "express services"—typically a 15-20% premium can reduce lead times by 30-40%.

Stage Five: Quality Inspection

This is the final line of defence for protecting brand reputation. Many Singapore enterprises mistakenly believe in "inspect after payment", but it should actually be "inspect before shipment".

AQL (Acceptable Quality Limit) Standards: Without explicit contract specifications, suppliers may adopt AQL 4.0 standards, meaning a 4% defect rate is "acceptable". For corporate gifts, this is unacceptable. We recommend explicitly requiring AQL 2.5 or stricter standards in contracts, and requesting suppliers provide inspection reports (with photographic evidence) before shipment.

Inspection Focus Points:

- Logo position, colour, and clarity

- Surface scratches, dents, or uneven coating

- Bottle cap seal testing (leak test)

- Packaging integrity and protective materials

Third-party inspection services: For large orders (1,000+ units) or high-value projects, consider engaging third-party inspection companies (such as SGS or Bureau Veritas). Whilst inspection fees range from SGD 300-800, they can prevent losses from entire batch defects.

Stage Six: Logistics and Delivery

Incoterms clarification: Ensure contracts clearly specify whether pricing is EXW (Ex Works), FOB (Free on Board), or DDP (Delivered Duty Paid). For Singapore enterprises, we recommend DDP terms, where suppliers handle all logistics and customs clearance, with goods delivered directly to your warehouse—this avoids unexpected customs or logistics charges.

Delivery scheduling: For large orders, consider "staged delivery" to avoid warehouse space pressure. For example, a 2,000-unit order could be delivered in two batches of 1,000 units each, spaced one month apart, reducing warehousing costs and cash flow pressure.

Key Success Factors (Decision Factors)

When procuring custom drinkware, Singapore enterprises must balance relationships among materials, techniques, and lead times. These three factors form a "trade-off triangle"—optimising one often requires compromising another.

Material vs Cost Trade-off

Stainless steel offers the best insulation and durability but comes at the highest cost. Glass provides a premium feel but is fragile with high transport costs. Tritan plastic is lightweight and affordable but less premium in brand image. The key question is: what is your primary objective—long-term brand building or short-term cost control?

If your enterprise prioritises long-term brand image (such as financial institutions or law firms), we recommend investing in stainless steel materials even if unit costs are 30-50% higher. If you're a startup with limited budget requiring rapid market entry, Tritan plastic is a pragmatic choice, with potential upgrades to stainless steel as your business scales.

Technique vs MOQ Trade-off

Laser engraving has low setup fees and low MOQ (50 units), but can only display single colours. Screen printing can display multiple colours with excellent durability, but requires higher MOQ (300+ units) to amortise setup fees. UV digital printing has no setup fees, suitable for small batches, but lower durability.

Decision framework: If your order quantity is below 200 units, prioritise laser engraving or UV digital printing. If order quantity exceeds 500 units and you require multi-colour logos, screen printing is the most cost-effective option. For orders between 200-500 units, calculate the "break-even point"—compare total costs of different techniques to identify the optimal solution.

Lead Time vs Quality Trade-off

Rapid delivery (7-10 days) typically means selecting from stock designs with limited customisation options. Fully customised designs (including mould opening and custom colours) require 30-45 day lead times. The key question is: is your project timeline-driven or quality-driven?

For urgent projects (such as event giveaways or conference gifts), we recommend "stock design + laser engraving" solutions, sacrificing some design uniqueness for delivery certainty. For annual corporate gifts or high-value client gifts, invest sufficient time in fully customised designs to ensure products perfectly align with brand image.

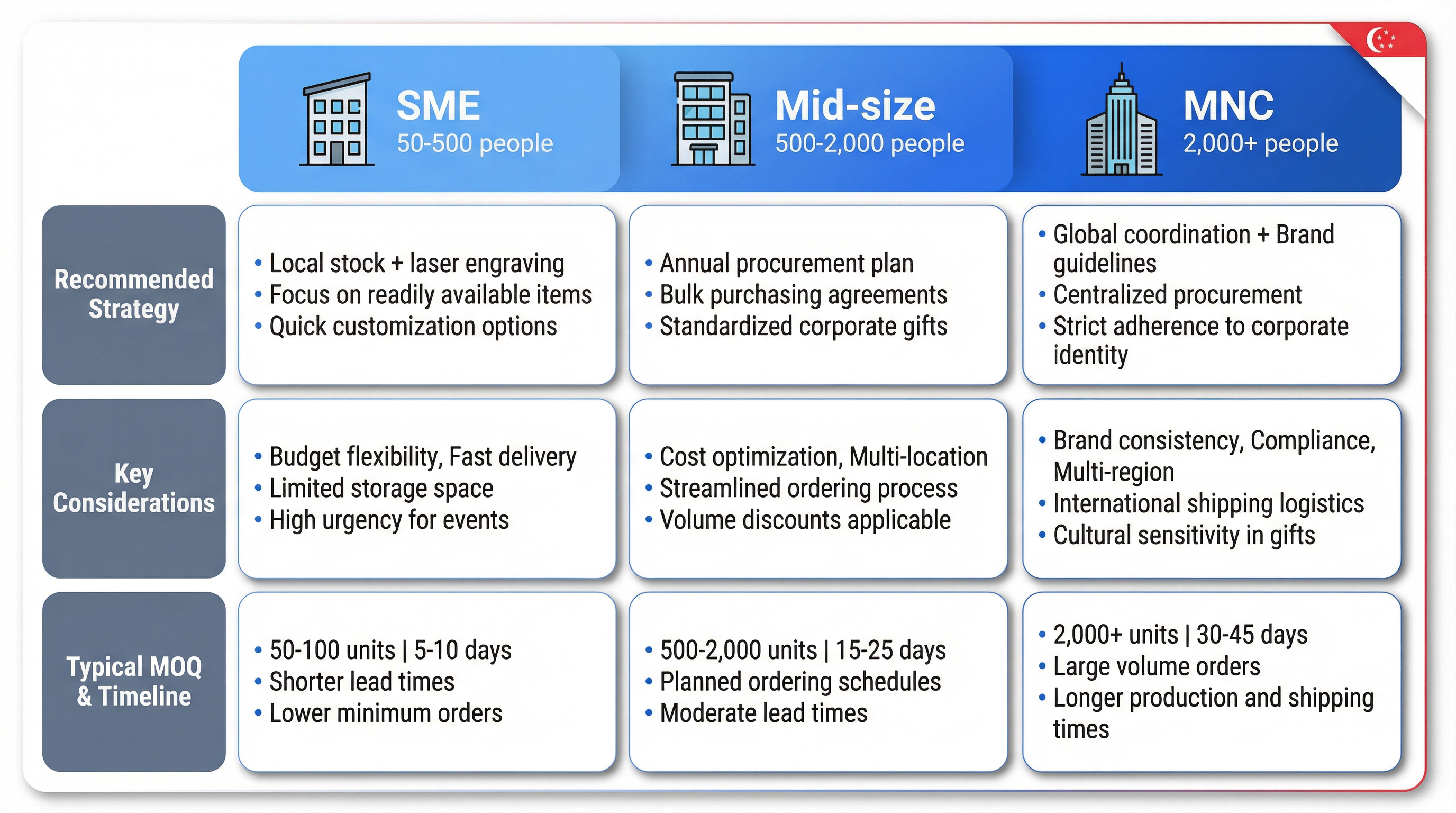

Strategic Recommendations for Different Enterprise Scales

Different-sized enterprises face distinct challenges and priorities when procuring custom drinkware. Below are differentiated strategies based on our experience assisting Singapore enterprises.

Startups / SMEs (Under 200 Employees)

Core challenges: Limited budgets, low order quantities, urgent timelines.

Recommended strategy:

- Prioritise local Singapore suppliers offering stock designs with laser engraving, MOQ as low as 50 units, lead times 5-7 working days.

- Avoid fully customised designs (such as custom colours or mould opening) to prevent setup fees exceeding product costs.

- Consider "trial orders" (50-100 units) to test market response before scaling up orders.

- Leverage local suppliers' flexibility—many are willing to provide free samples or design consultation services for first-time clients.

Cost control tip: If your budget is extremely tight, consider "co-branding" with other startups to share MOQ and setup fees, reducing per-unit costs.

Mid-sized Enterprises (200-1,000 Employees)

Core challenges: Balancing cost and quality, managing multiple office locations or departments.

Recommended strategy:

- Establish annual procurement plans, locking in lower unit pricing through "blanket orders" (total quantity orders with staged delivery).

- Select 1-2 "core suppliers" for long-term partnerships, securing priority service and preferential pricing.

- Implement "tiered procurement" strategies—standard employees receive Tritan plastic bottles (SGD 5-7), whilst management and clients receive stainless steel bottles (SGD 10-15).

- Establish internal "design approval workflows" to avoid design mockup iteration delays.

Risk management tip: Maintain 10-15% "safety stock" to address sudden demand (such as new employee onboarding or unexpected client gifts).

Large Enterprises / MNCs (Over 1,000 Employees)

Core challenges: Global brand consistency, compliance requirements, multi-region distribution coordination.

Recommended strategy:

- Establish "global procurement frameworks" with designated suppliers providing consistent products across all regions, ensuring brand consistency.

- Require suppliers to provide compliance certifications (such as SFA food safety certification, ISO 9001 quality management certification).

- Implement "centralised procurement, regional distribution" models—bulk orders placed by headquarters, with staged distribution to regional offices according to requirements.

- Establish stringent "quality control protocols", including third-party inspection and AQL 1.5 or stricter standards.

Sustainability considerations: For listed companies or enterprises with ESG (Environmental, Social, Governance) reporting requirements, prioritise suppliers offering sustainable materials (such as recycled stainless steel or biodegradable packaging), quantifying environmental contributions in annual reports.

Special Regulations and Pitfall Avoidance Guide for Singapore Market

Singapore enterprises must consider local regulations, cultural taboos, and logistics constraints when procuring custom drinkware. Below are key considerations specific to the Singapore market.

Food Safety Regulations

All drinkware materials in contact with beverages must comply with Singapore Food Agency (SFA) food safety standards. Stainless steel must be SUS304 (18/8 food-grade stainless steel), plastic materials must be BPA-free, and glass must be lead-free.

Pitfall avoidance: Request suppliers provide material safety certifications (such as FDA or LFGB certifications). If suppliers cannot provide certifications, this is a red flag—do not proceed with orders.

GST and Import Duties

Singapore's GST rate is 7%, applicable to all imported goods. If your supplier is overseas, ensure contracts clearly specify whether pricing is inclusive or exclusive of GST. We recommend requiring suppliers to provide DDP (Delivered Duty Paid) quotes, where all taxes and duties are included in the quoted price, avoiding unexpected costs.

Corporate Gifting Cultural Taboos

In Singapore's multicultural society, corporate gift-giving must respect different ethnic and religious customs:

- Avoid alcohol-related designs: Singapore has a significant Muslim population; alcohol-themed designs may be inappropriate.

- Avoid overly expensive gifts: Singapore's anti-corruption laws (Prevention of Corruption Act) stipulate that public sector employees cannot accept gifts exceeding SGD 50. If your clients include government agencies, ensure gift values remain within legal limits.

- Respect colour preferences: In Chinese culture, red symbolises luck; in Malay culture, green is preferred; in Indian culture, avoid black (associated with mourning).

Logistics and Warehousing Constraints

Singapore has limited land area with high warehousing costs. For large orders (1,000+ units), consider:

- Staged delivery: Avoid receiving entire batches at once to reduce warehousing pressure.

- Direct delivery to event venues: If products are for specific events, arrange suppliers to deliver directly to venues, eliminating intermediate warehousing.

- Utilise suppliers' warehousing services: Some local suppliers offer free short-term warehousing (1-2 months), allowing flexible collection according to requirements.

Zero Waste Masterplan Compliance

The Singapore government is advancing the "Zero Waste Masterplan", encouraging enterprises to reduce single-use plastics. Choosing reusable custom drinkware aligns with this policy direction, potentially qualifying for:

- Green procurement incentives: Some government agencies or large enterprises offer procurement preference or price premiums for eco-friendly products.

- CSR reporting content: Quantify environmental contributions in annual CSR reports (such as "distributing 1,000 reusable bottles, reducing approximately 50,000 single-use plastic bottles annually").

Frequently Asked Questions (Q&A for NLP)

Q1: What is the typical MOQ for custom drinkware in Singapore?

MOQ varies by material and technique. Laser engraving on stainless steel can be as low as 50 units; screen printing typically requires 300+ units; fully customised designs (including mould opening) may require 1,000+ units. Local Singapore suppliers generally offer more flexible MOQs than overseas suppliers.

Q2: How long does the entire custom drinkware process take?

Standard processes require 20-35 working days, including design mockup confirmation (5-10 days), sample production (3-5 days), bulk production (15-20 days), and logistics (2-5 days). Express services can reduce to 10-15 working days but typically incur 15-20% premiums.

Q3: How can I ensure print quality won't fade?

Choose durable printing techniques such as laser engraving (permanent, won't fade) or powder coating combined with screen printing (maintains 3-5 years). Avoid heat transfer printing (fades within 6-12 months). Request suppliers provide "durability test reports" demonstrating print quality after multiple washes.

Q4: What are the cost differences between local Singapore suppliers and overseas suppliers?

Local suppliers' unit costs are typically 10-20% higher but offer advantages including shorter lead times (5-7 days vs 30-45 days), lower MOQs (50 units vs 500 units), and easier communication and after-sales service. For urgent projects or small batches, local suppliers are more cost-effective; for large orders (1,000+ units), overseas suppliers offer price advantages.

Q5: How do I handle quality issues if defective products are discovered after delivery?

Establish clear "quality assurance terms" in contracts, including defect rate standards (such as AQL 2.5), return and exchange policies, and compensation mechanisms. We recommend "inspect before shipment" rather than "inspect after delivery"—request suppliers provide inspection reports with photographic evidence before shipment. If defects are discovered post-delivery, immediately document with photos and contact suppliers; reputable suppliers typically offer free replacements or partial refunds.

Q6: Can I request samples before placing bulk orders?

Yes, most suppliers offer sample services. Sample fees typically range from SGD 20-50 per unit, with some suppliers waiving fees or providing refunds upon bulk order placement. We strongly recommend requesting samples to verify actual product quality, print effects, and material feel before committing to bulk orders.

Conclusion & Next Steps

Custom drinkware procurement is a complex decision encompassing budget control, brand image, compliance requirements, and supply chain management. Singapore enterprises must consider material selection, printing techniques, MOQ negotiations, lead time management, and quality control throughout the process. The key to success lies in clarifying your core objectives (cost vs quality vs timeline), selecting appropriate suppliers (local vs overseas), and establishing stringent quality control protocols.

Whether you're a startup requiring rapid market entry or an MNC pursuing global brand consistency, we hope this guide provides practical decision-making frameworks and pitfall avoidance strategies.

Ready to Start Your Custom Drinkware Project?

Understand our production process and quality standards: View Our Production Process

Begin your project immediately: Contact Our Team. We'll respond to your enquiry within 24 hours and provide professional recommendations tailored to your specific requirements.

Related Articles

Singapore Custom Drinkware MOQ Complete Guide: Minimum Order Quantities for Corporate Procurement

Comprehensive guide to Minimum Order Quantities (MOQ) for Singapore businesses procuring custom drinkware. Learn how to select appropriate MOQ based on company size, balance costs and inventory risk, and navigate local suppliers vs direct China procurement for optimal procurement decisions.

How Long Does It Take to Produce Custom Drinkware in Singapore? A Complete Timeline Guide

Production timelines for custom drinkware in Singapore range from 10 days to 90 days. Complete guide covering material types, seasonal planning, risk mitigation, and Singapore-specific factors like CNY factory shutdowns.

Strategic Tooling Cost Amortization for Custom Drinkware Molds: A Singapore Procurement Guide

For Singapore-based B2B firms venturing into custom drinkware, the initial tooling cost for bespoke molds represents a significant capital investment. This comprehensive guide details effective strategies for **mold amortization**, transforming this high fixed cost into a manageable, per-unit operational expense. We explore the financial frameworks, including unit-based and time-based amortization, and the critical role of accurate volume forecasting in cost recovery. Furthermore, the article provides a deep dive into **procurement strategy**, examining the nuances of tooling ownership models—Full, Shared, and Supplier-Financed—and the negotiation tactics required to secure favourable terms. A key focus is placed on risk mitigation, emphasising the importance of material selection, proactive mold maintenance, and the creation of a tooling reserve. Finally, we analyse the nexus between logistics, quality control, and the amortization horizon, providing a robust, procurement-focused framework to leverage custom tooling as a strategic, long-term asset in the competitive Singapore market.

Interested in Custom Drinkware?

Contact our team to discuss your requirements and receive a personalized quote for your corporate gifting needs.